RecoFIT®

The reconstruction of existing switchgear and equipment, the replacement of low-oil circuit breakers with vacuum technology, and the implementation of new protection and control technology have been part of our services since 1997. We also offer the use of load management controllers for controlled nominal current increases and the retrofitting of monitoring sensors, e.g., for insulation monitoring or temperature monitoring, into existing equipment. This saves investment and maintenance costs, even for new systems. Some of the retrofitting can be carried out during ongoing operation if system components can be safely isolated and access to the current-carrying contacts and connections is guaranteed. Current and voltage transformers, generators, motors, transformers, and capacitors can also be integrated into the monitoring system.

These systems must be tailored to the specific operating conditions; therefore, we recommend software adaptation and a parameter comparison test on-site during the system adaptation period.

SERVICE OVERVIEW RecoFIT® Medium voltage

Since 1997, we have been operating as an internationally experienced, independent engineering service provider in the field of medium- and high-voltage technology. We develop, design, and test gas- and air-insulated switchgear families and all switching devices (circuit breakers, load-break switches, disconnectors, short-circuit-proof earthing switches, short-circuiting devices, arc fault limiters), including the drives used in these systems. In the medium-voltage range (6 kV to 52 kV) and high-voltage range (72.5 kV to 123 kV), we use exclusively nitrogen or dry air as the insulating gas in combination with vacuum switching technology. I presented our experience in the field of nitrogen insulation at the CIRED in June 2015 in Lyon under the topic "Replacing SF6." In addition to new developments, we also offer professional upgrading of medium-voltage switchgear.

Since the introduction of the new Industrial Safety Ordinance (Federal Law Gazette Part 1, G5702 of February 6, 2015, No. 4, as of July 13, 2015), the importance of personal safety has increased dramatically. Risk assessments and protective measures are clearly defined. As a result, there is no longer any "grandfathering" for switchgear that does not meet the state of the art. Rather, the operation of systems without adequate protection for people or property is no longer permitted. Since this is a legal gazette, insurers will likely examine the circumstances very carefully in the event of a claim involving non-upgraded older systems.

In this context, we offer to develop cost-effective, sustainable technical solutions and prepare relevant risk assessments.

We'll create a customized offer for you! Here's what we can do for you (examples):

- Dimensioning, pressure calculation, strength verification, manufacturing, and installation of arc-proof pressure relief ducts, discharge openings, special doors, pressure relief flaps, opening cross-sections, and shutters.

- Arc-fault pressure calculation for existing systems or when installing new switchgear in stations, buildings, basements, or industrial facilities.

- Thermal upgrades through retrofitting arc-proof convective or forced ventilation units with redundant safety control.

- RecoFIT®/Retrofit upgrades of switchgear (replacement of outdated, maintenance-intensive circuit breakers, reconstruction of drives and trip units).

- Reconstruction or retrofitting of interlocks.

- Upgrading of switchgear including aging assessment of insulation (post insulators, plug-in plates, barriers), contacts, and connections. Installation of plug-in units.

- Upgrading for higher rated current loads or improved insulation strength.

- Load management systems with direct wireless temperature measurement on high-voltage connections and contacts. Including monitoring and connection to the control system

- Design of special earthing systems (e.g., busbar earthing switches)

- Connection of new to existing systems according to DIN VDE (IEC) 62271-1, -200, -203

- Repair of special switchgear

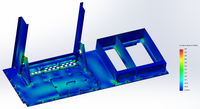

- Strength verification for the compressive and tensile strength of switchgear doors and walls, as well as doors, ducts, and room discharge openings

- Wind load calculation for outdoor systems and station buildings

- Small-scale production for selected assemblies

- On-site assembly and modification of primary equipment (cabinets, trolleys, plug-in units, switchgear)

- Selection and installation of surge arresters

- On-site nominal power-frequency withstand voltage test or lightning impulse voltage test according to IEC 62271-200 or -1 and high-current resistance measurement with a microohmmeter prior to commissioning

- Replacement and inspection of switchgear protection equipment (in collaboration with our RecoFIT®/Retrofit partner: Papst) Elektroanlagenbau GmbH)

- Replacement of current and voltage transformers

- Installation and optimal connection of fast arc fault limiters or short-circuit earthing switches

- Radiation detection for open arc faults, e.g., according to IEEE 1584, to demonstrate the required class of protective equipment and the minimum distance for persons

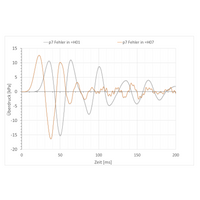

- Multiphysical simulations (electrical and magnetic fields, EMC, heating, static and dynamic strength for the TAB networks of utility companies)

- Independent expert reports (e.g., damage reports, fault analysis)

- Switching operations after approval with switching discussion up to 30 kV

- Switching operations and inspection of medium-voltage systems on excavators, construction sites, solar power plants, biogas plants, and wind turbines with dedicated PPE and high-altitude abseiling and rescue equipment, verification according to BGR 198/BGR 199 and health certificate G41

- Reconstruction or conversion of 3-phase to 2-phase railway switchgear for 16 2/3 Hz

- Declarations of conformity and Operating certificate for systems upgraded by us

- Documentation and change management (language according to customer requirements)

- On-site assessments, worldwide

Upgrading of stations

- On-site measurement of the station

- Concept development

- CAD design

- Arc fault pressure calculation

- Strength verification using FEM simulation

- Replacement of MV switchgear (if necessary)

- Installation work

- Cable testing

- Acceptance of the upgraded station